![]()

THE CONCEPT | MTN STEMS | DM STEMS | PEDALS | CRANKS

COMING IN LATE SPRING

Teknika Development

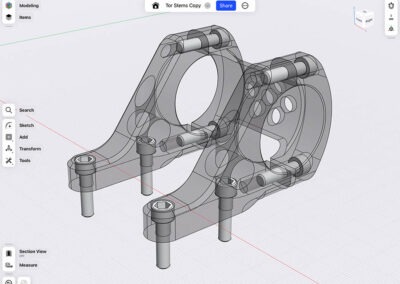

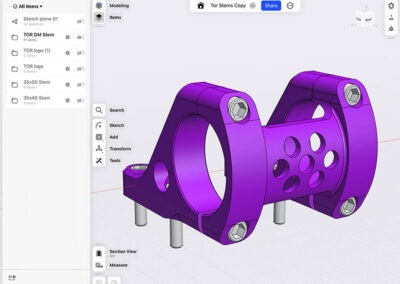

The Teknika products (1) start with a premise and concept; either something patently different or a twist on something that hasn’t been taken as far as it can go. Then (2) we spend a lot of time working this out virtually in Shapr3D which is a fantastic industrial design program that fully integrates with Solidworks and CAD/CAM software. Once we have something we believe is a solid concept, we (3) 3D print it in carbon composite with our Markforged Mark II printer. The print isn’t quite strong enough to ride, but we can mount it to a bike and check fit and function. From there, (4) we go to CNC machined samples to ride test. Changes and iterations are done throughout the process. Once we settle on a finished design, we (5) create final samples that go through a full run of industry standard testing.

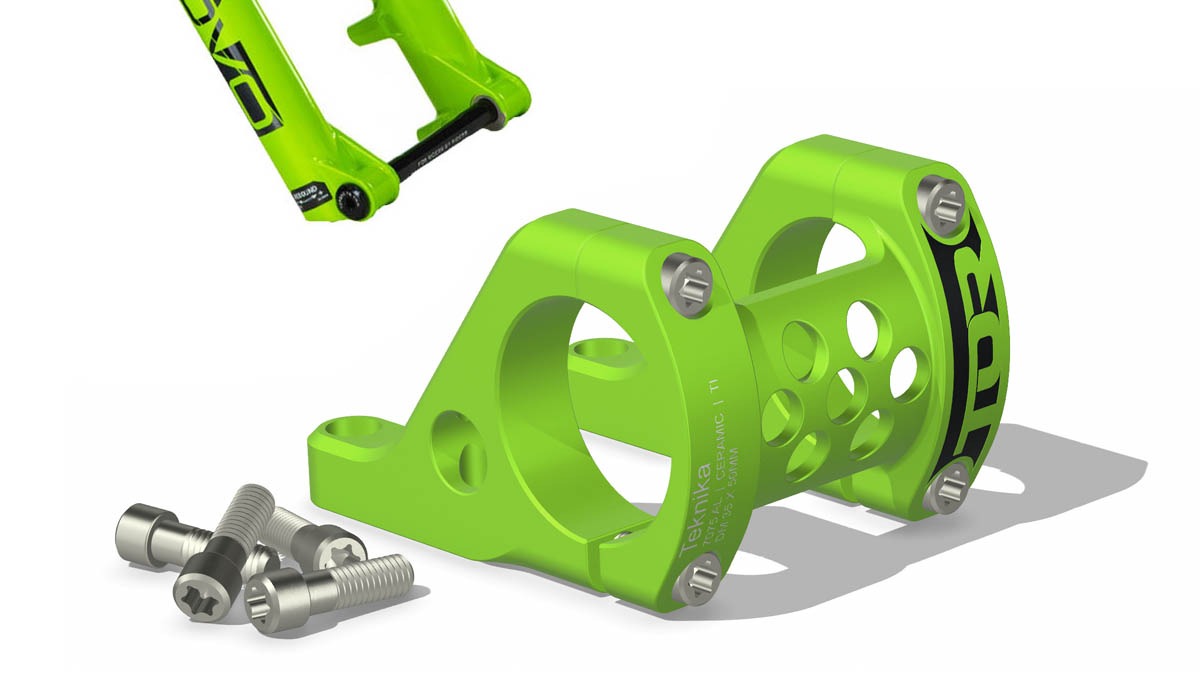

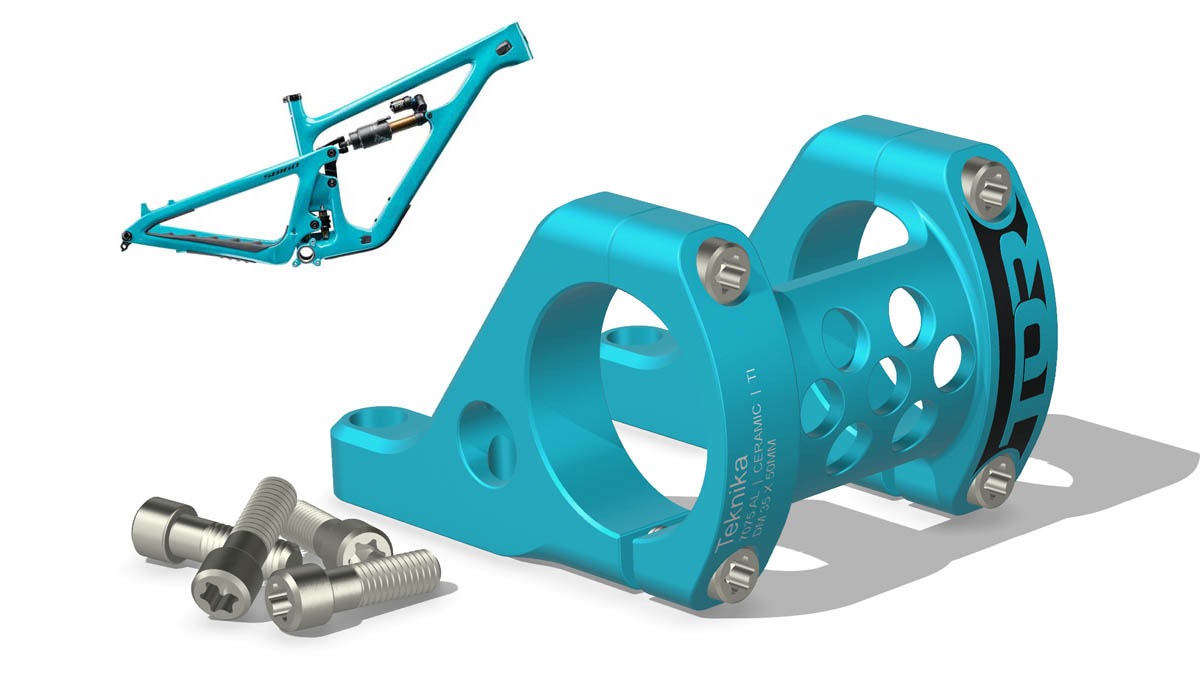

Here are some images of the development of the direct mount stems.

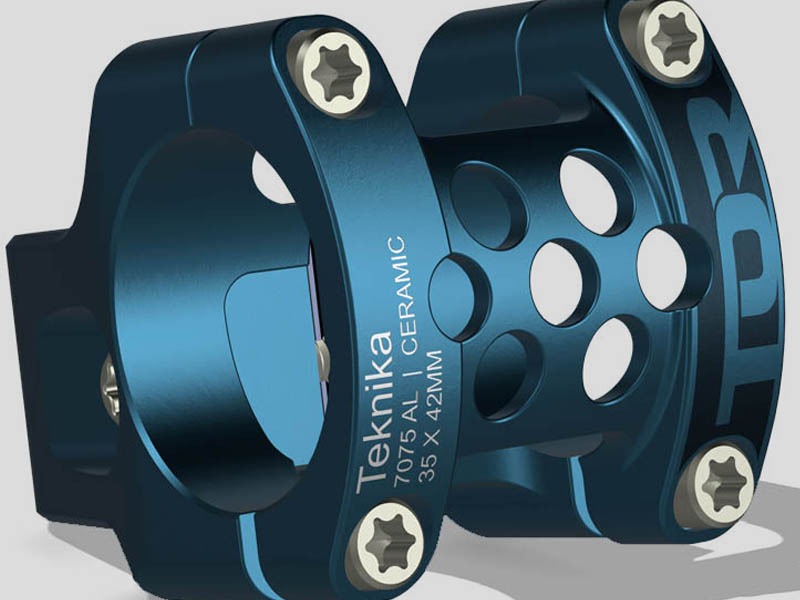

DIRECT MOUNT STEMS

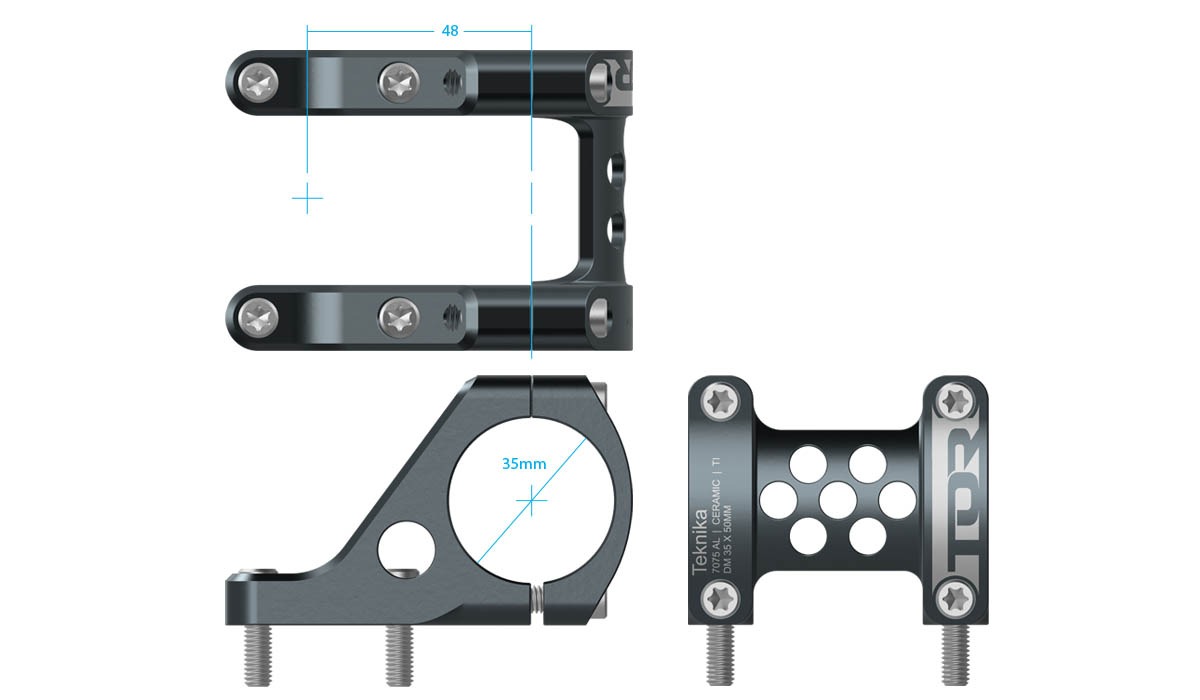

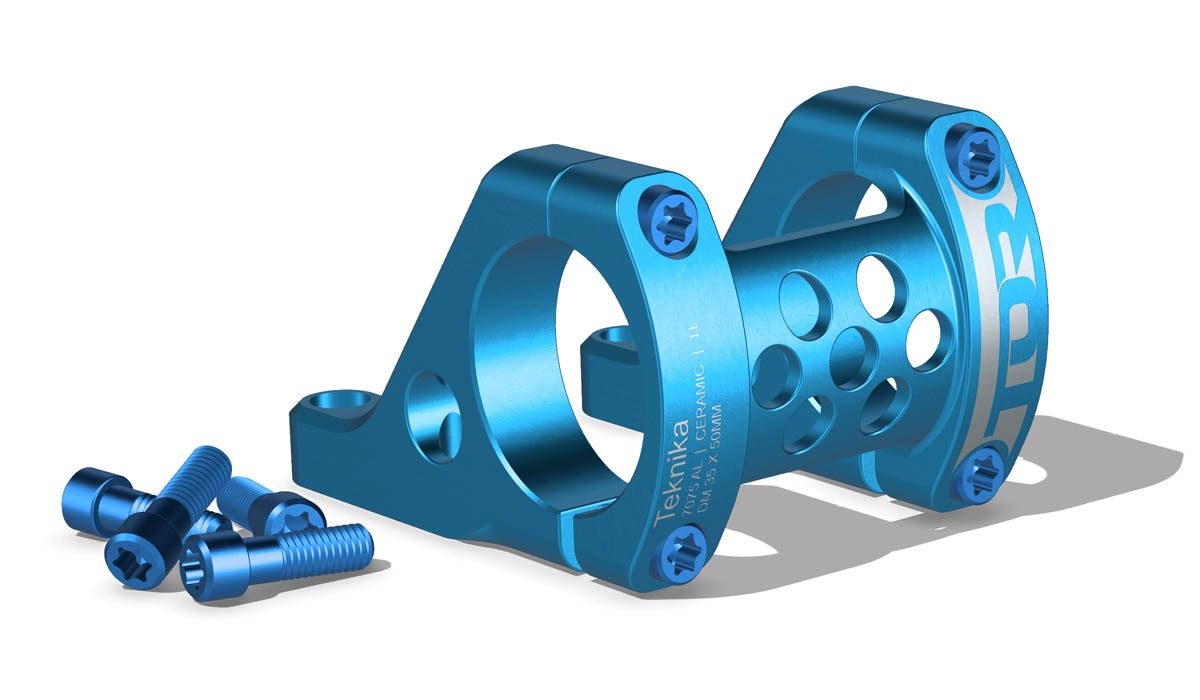

Our DM stems are 7075 Aluminum and feature a unique double-windowed counter-bore area for the front triple clamp bolts that keeps things tight and light. It fits 35mm diameter handlebars and has a 48mm reach. Available in custom Cerakote colors – SEE CERAKOTE COLOR SWATCHES

- 7075 AL / Titanium Hardware / Ceramic Finish

- 35mm Bars / 50mm Reach / 132g

- Comes with ti triple clamp mounting bolts

Black w/ silver logos & gold pins – $179.99

Black logos +$12

Choice of hardware color +$20

Custom color w/ silver logos +$40

Custom color & logos +$70

PRE-ORDER ($50 deposit)

Our first production run will be limited. Reserve your’s now.

CUSTOM COLORS: We will email/call you to select custom colors so we can make sure we get you exactly what you want.

Teknika Development

The Teknika products (1) start with a premise and concept; either something patently different or a twist on something that hasn’t been taken as far as it can go. Then (2) we spend a lot of time working this out virtually in Shapr3D which is a fantastic industrial design program that fully integrates with Solidworks and CAD/CAM software. Once we have something we believe is a solid concept, we (3) 3D print it in carbon composite with our Markforged Mark II printer. The print isn’t quite strong enough to ride, but we can mount it to a bike and check fit and function. From there, (4) we go to CNC machined samples to ride test. Changes and iterations are done throughout the process. Once we settle on a finished design, we (5) create final samples that go through a full run of industry standard testing.

Here are some images of the development of the direct mount stems.