![]()

THE CONCEPT | MTN STEMS | DM STEMS | PEDALS | CRANKS

COMING IN LATE SPRING

Teknika Development

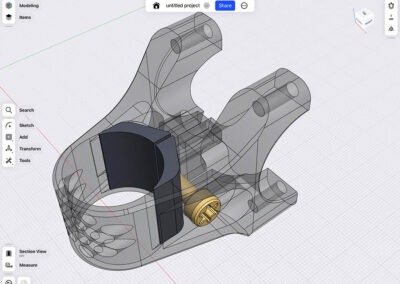

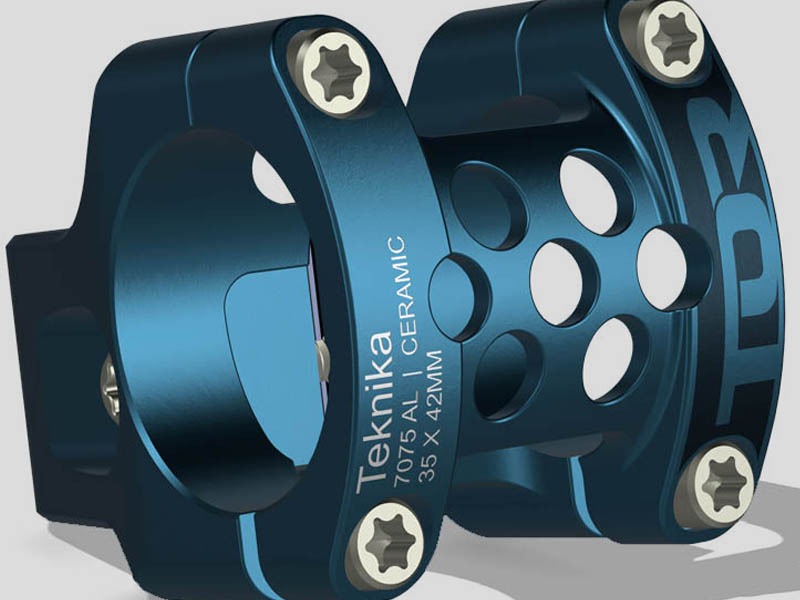

The Teknika products (1) start with a premise and concept; either something patently different or a twist on something that hasn’t been taken as far as it can go. Then (2) we spend a lot of time working this out virtually in Shapr3D which is a fantastic industrial design program that fully integrates with Solidworks and CAD/CAM software. Once we have something we believe is a solid concept, we (3) 3D print it in carbon composite with our Markforged Mark II printer. The print isn’t quite strong enough to ride, but we can mount it to a bike and check fit and function. From there, (4) we go to CNC machined samples to ride test. Changes and iterations are done throughout the process. Once we settle on a finished design, we (5) create final samples that go through a full run of industry standard testing.

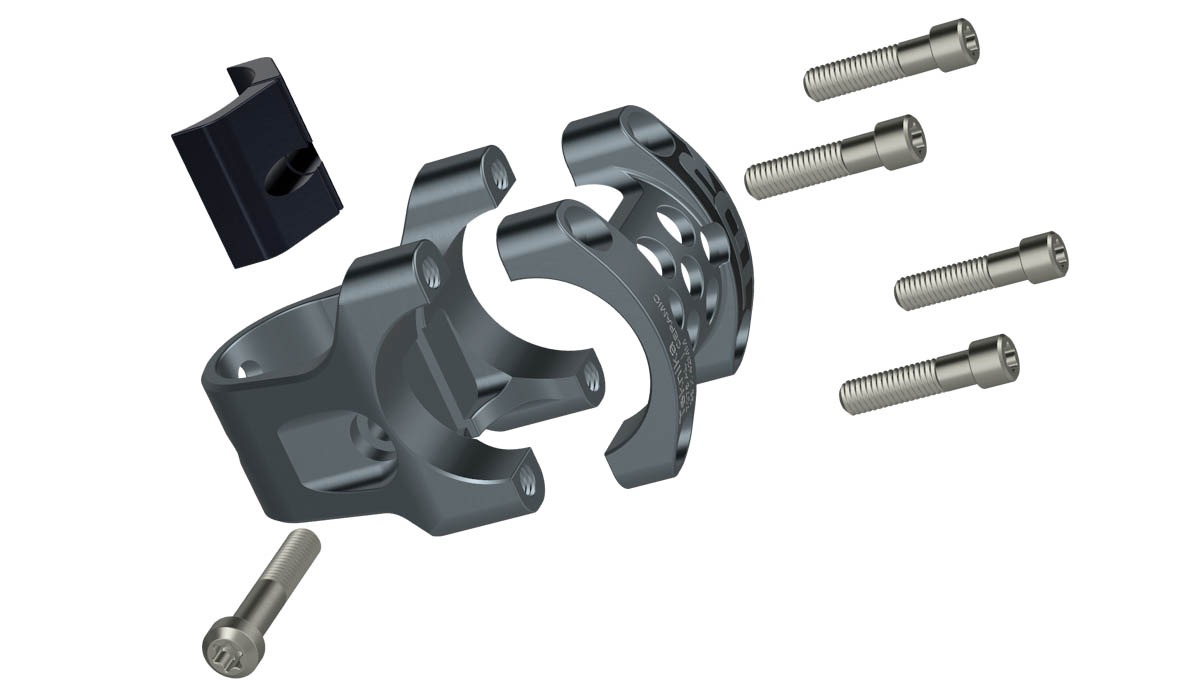

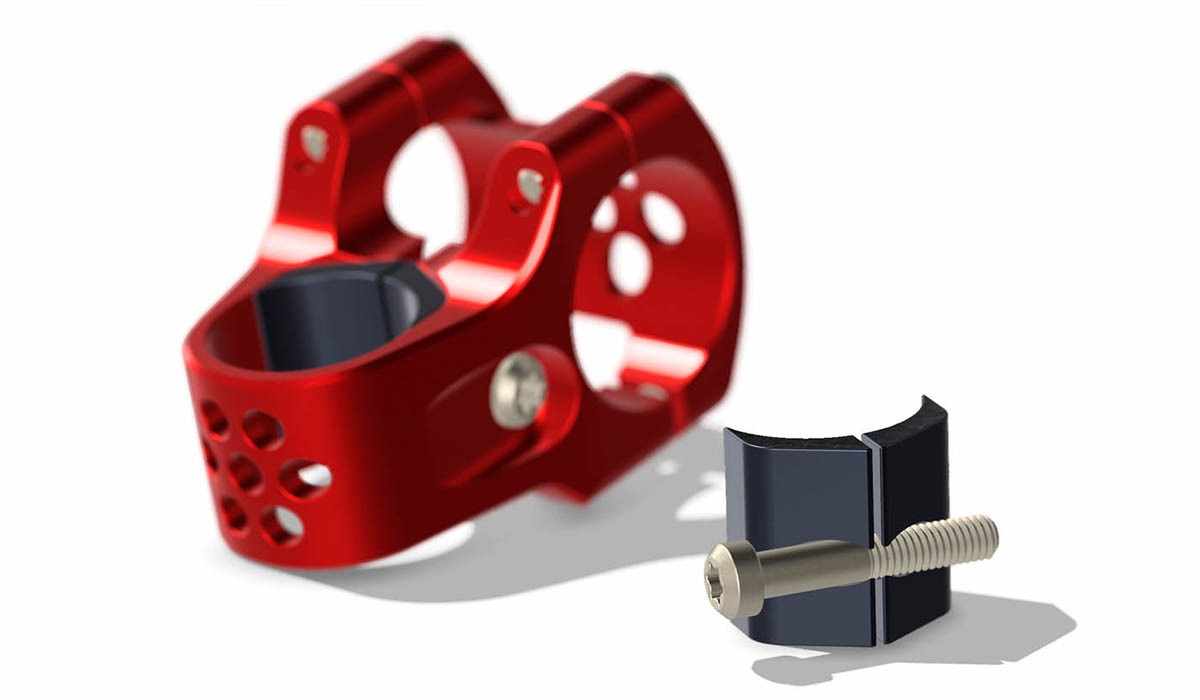

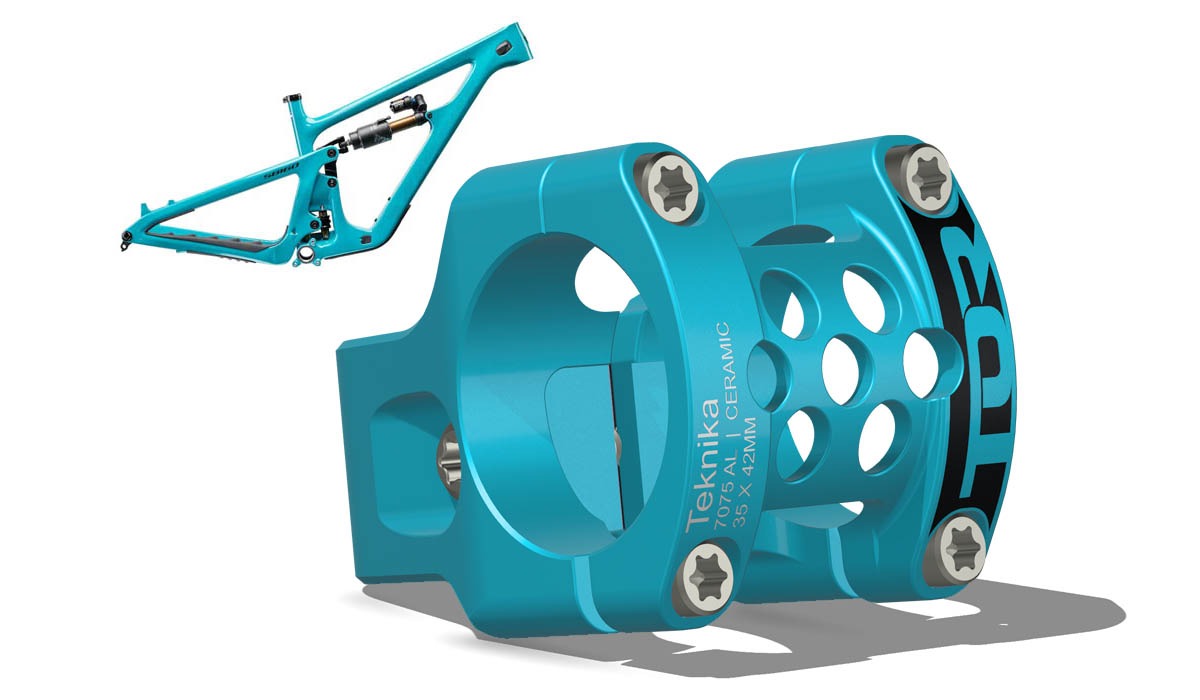

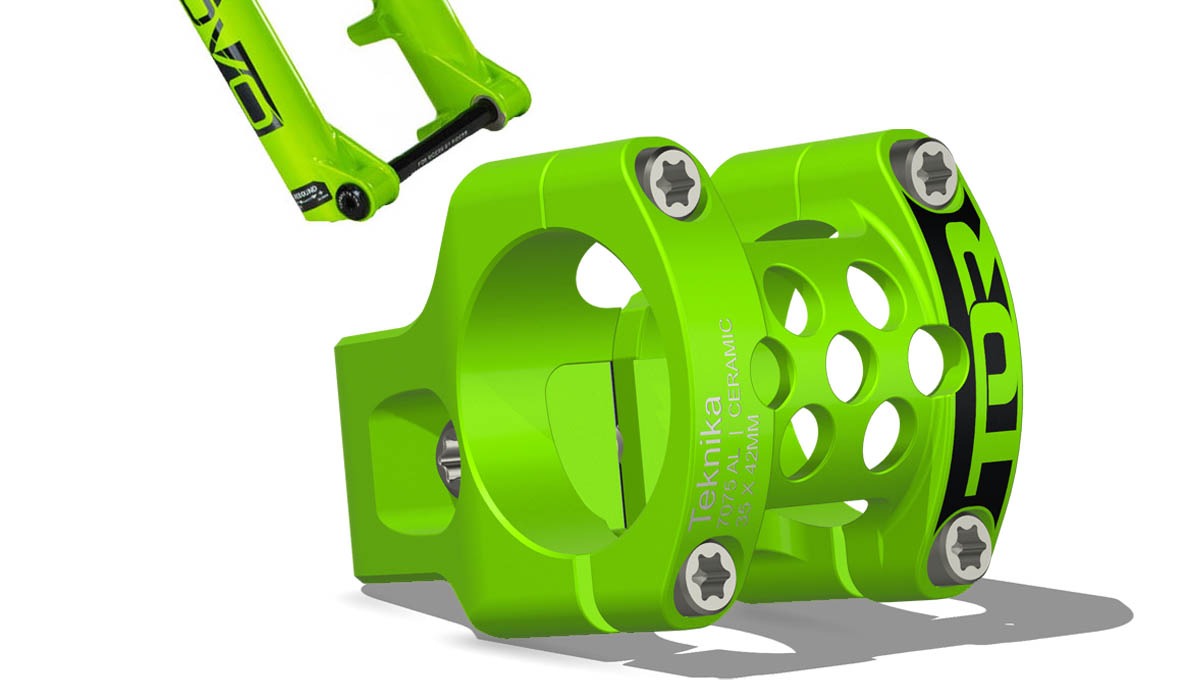

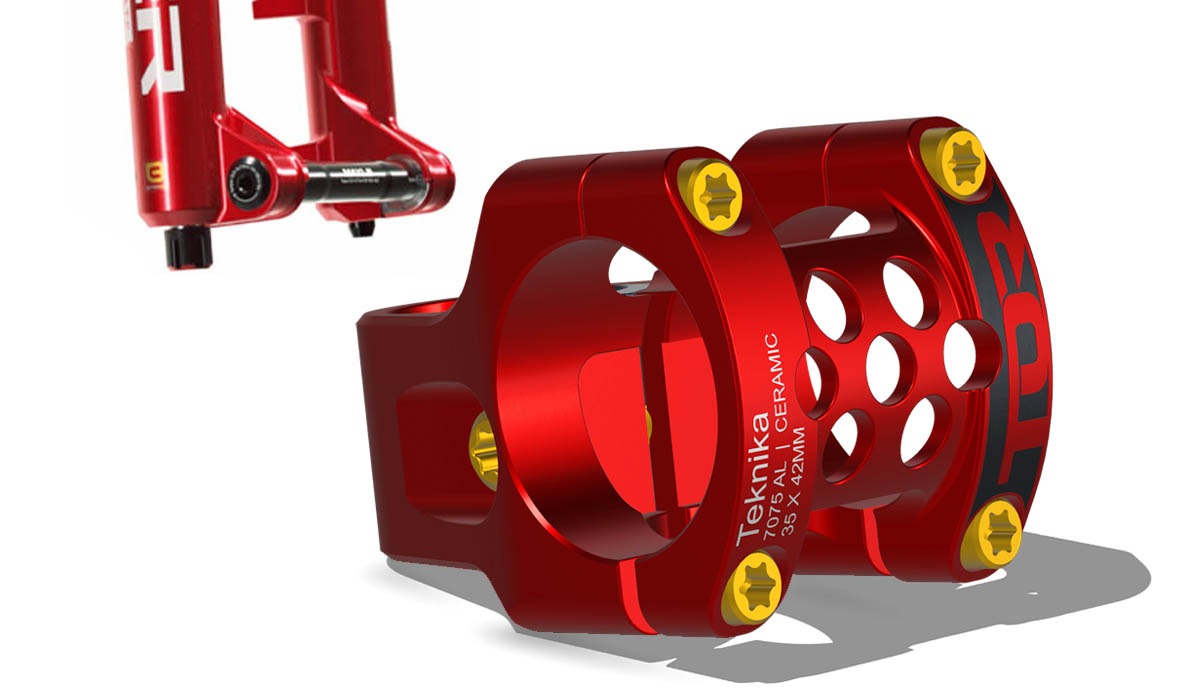

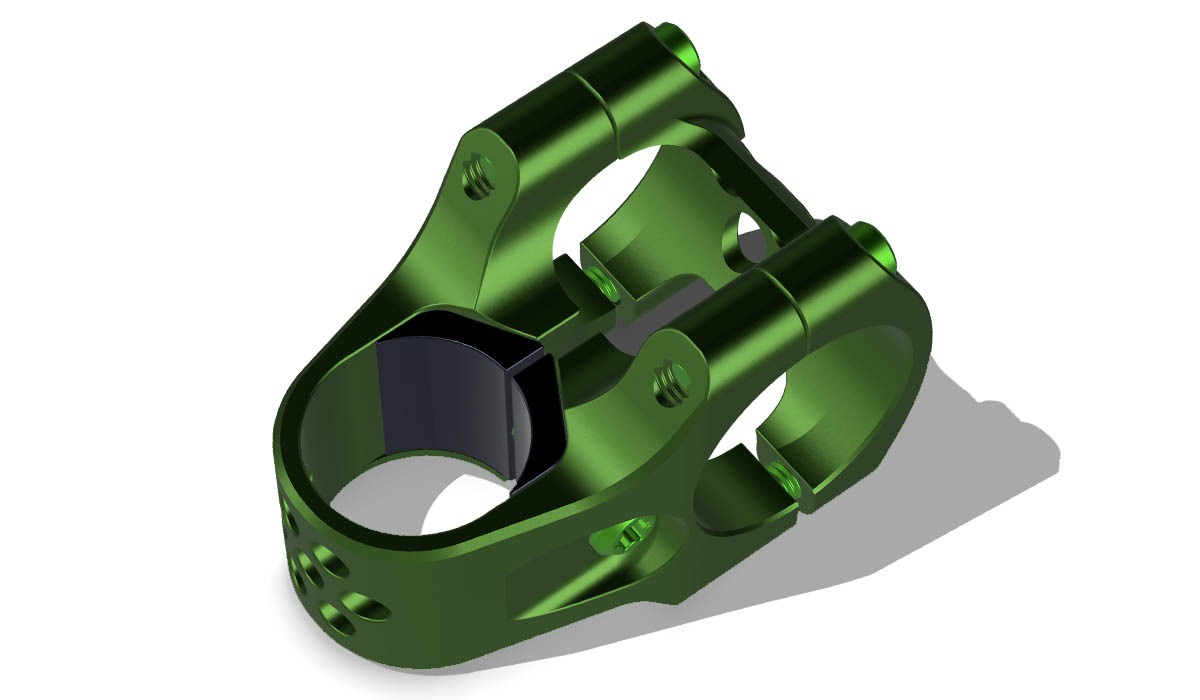

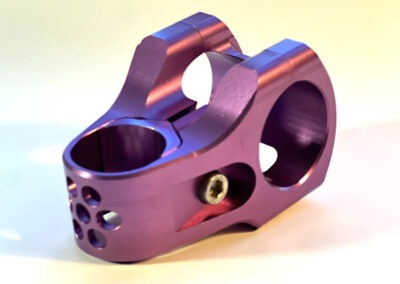

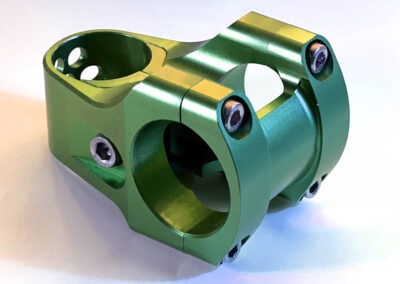

Here are some images of the development of the mountain stems. Click here to see a video of a carbon 3D print

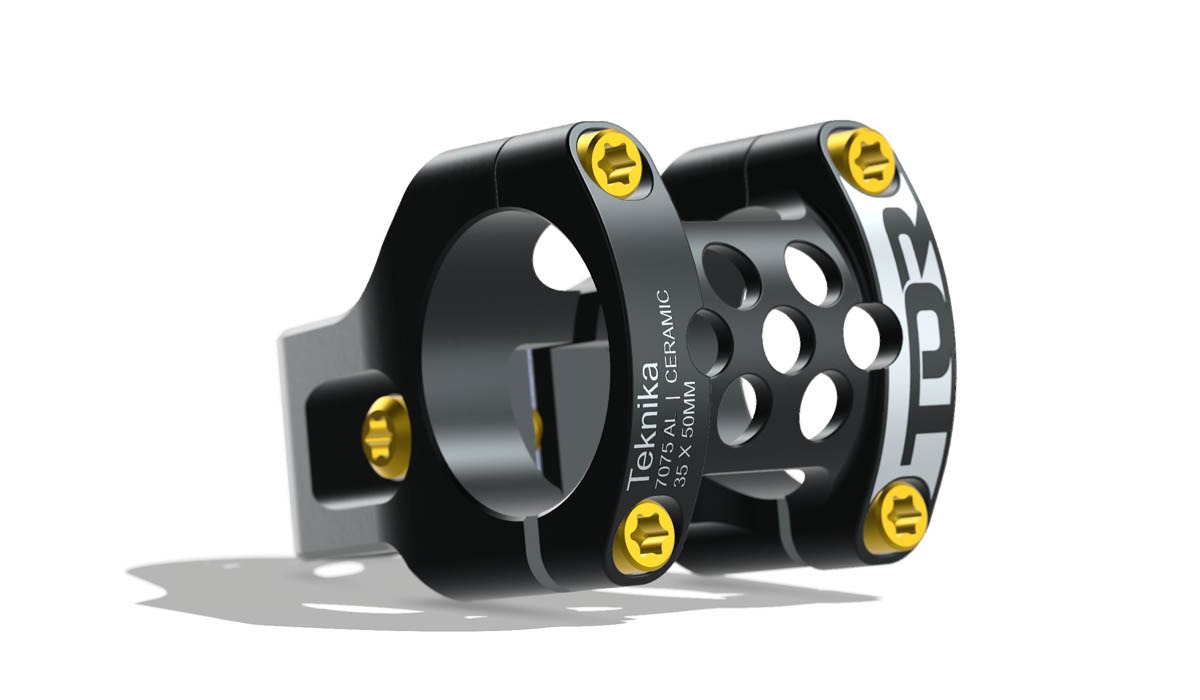

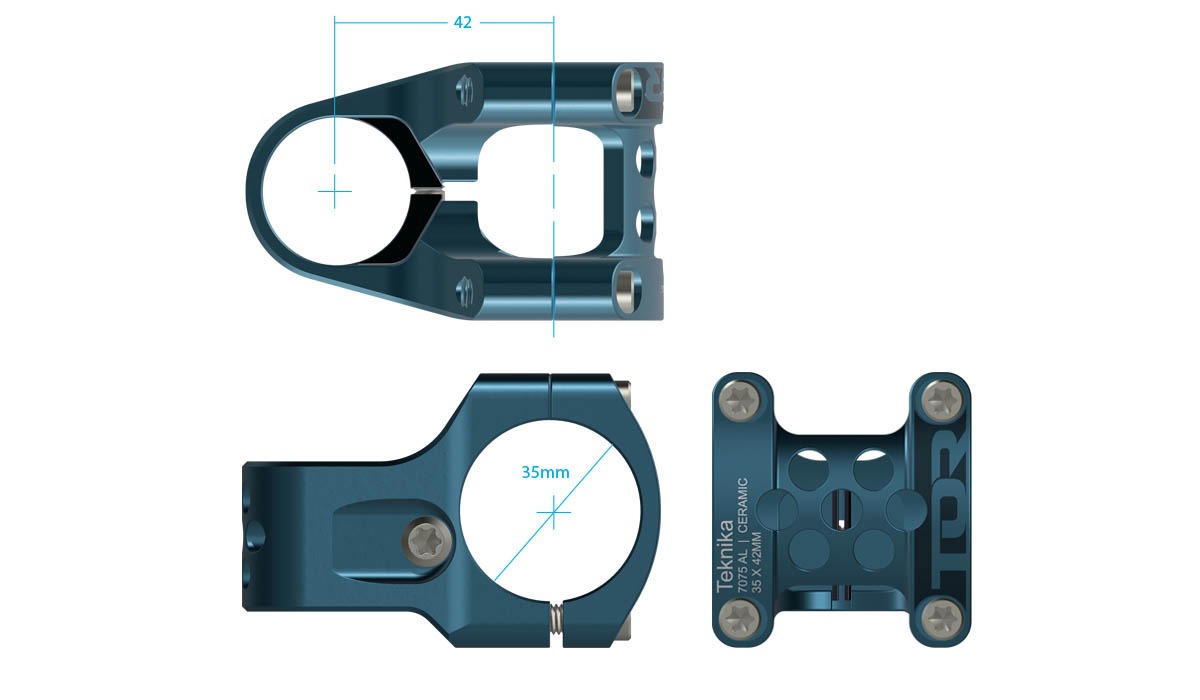

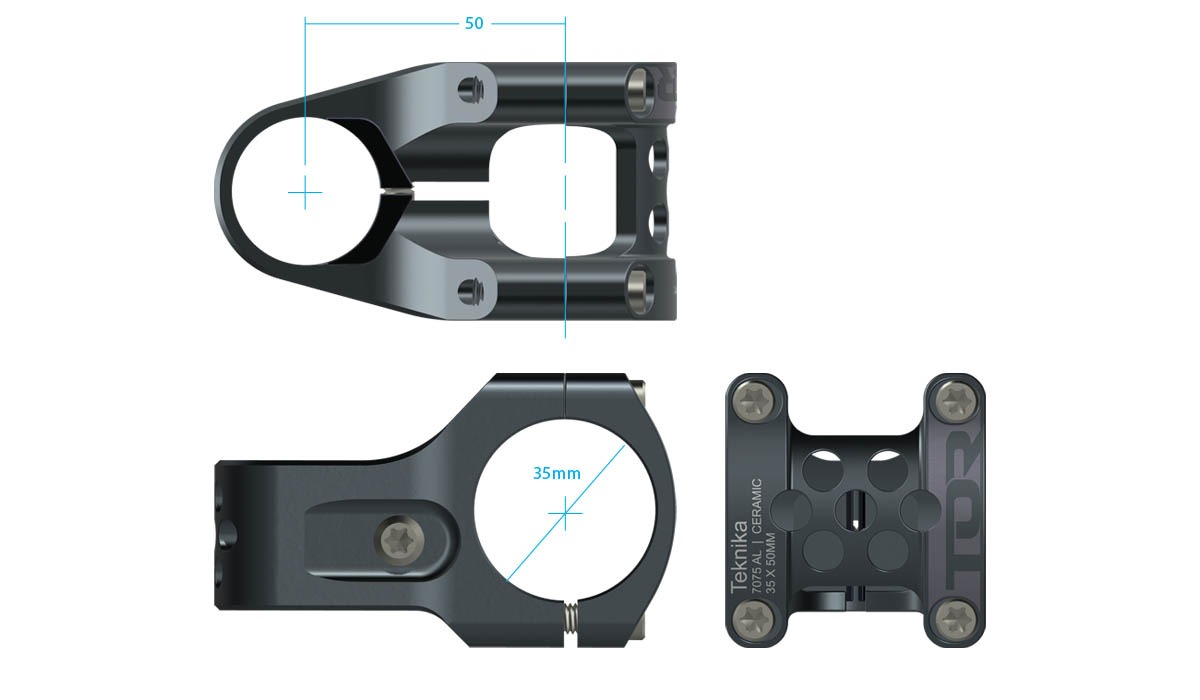

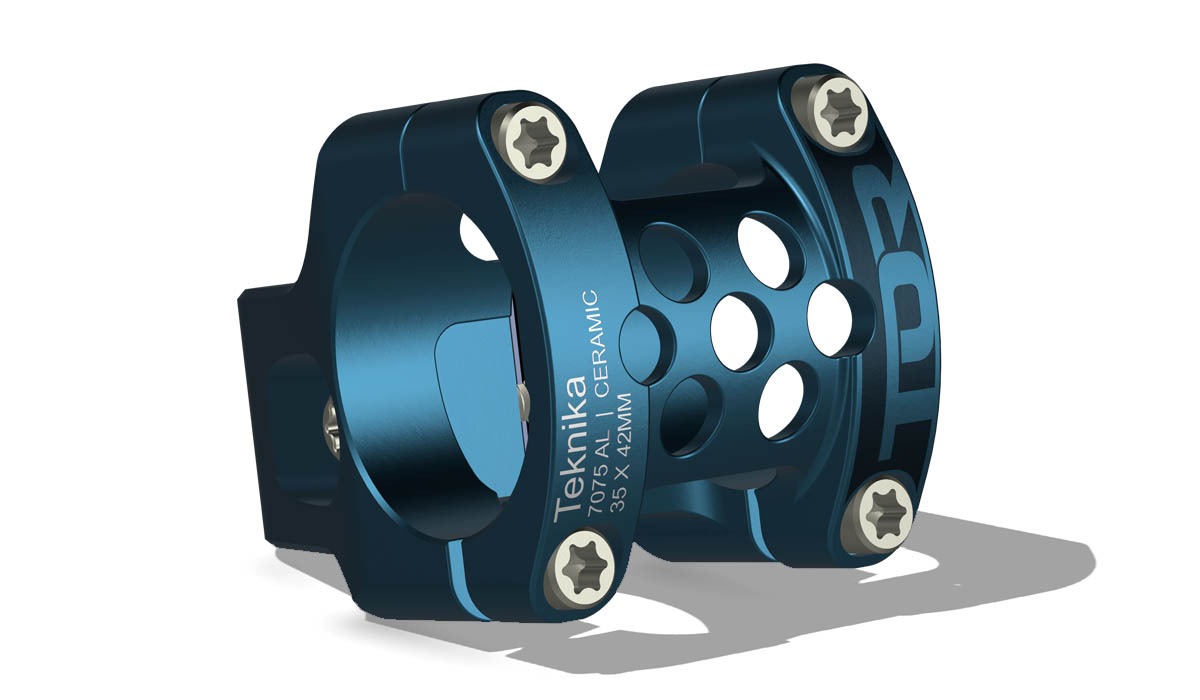

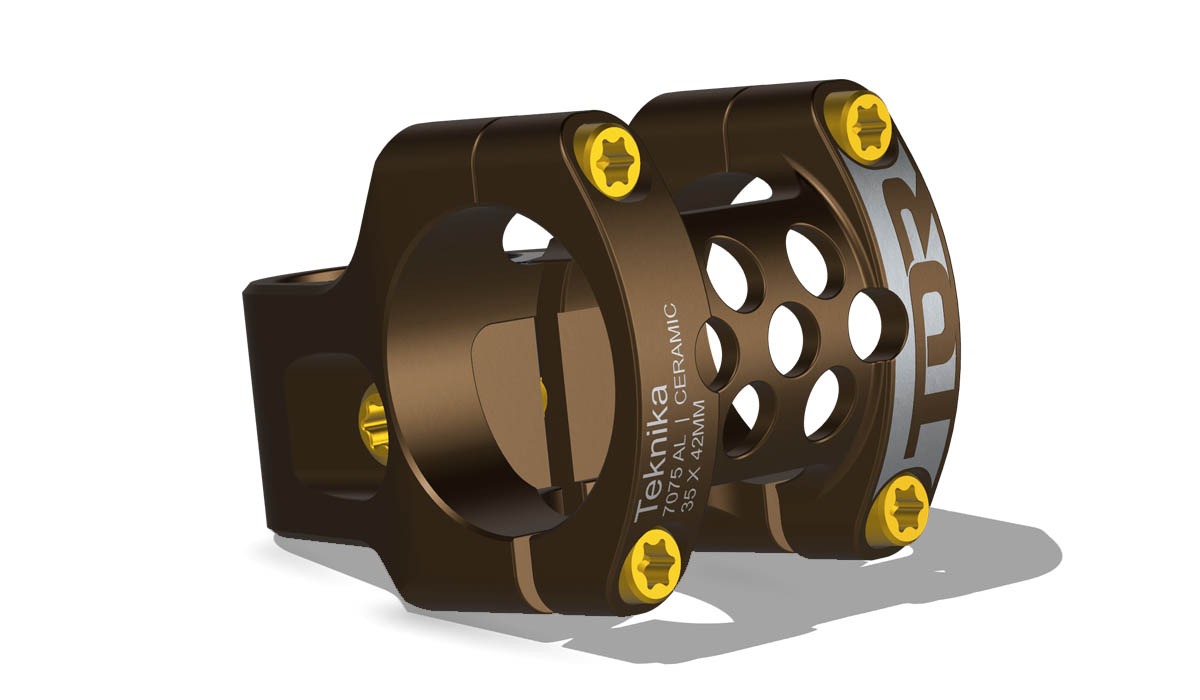

CNC MTN STEMS

These 7075 Al stems use a constrictor system. The two wedges push back into the steer tube, grabbing it nearly all the way around rather than just pinching at the bolt. This not only more secure, it allows for an even lighter overall weight. It fits 35mm diameter handlebars and comes in two lengths – 42 & 50mm. Available in custom Cerakote colors – SEE CERAKOTE COLOR SWATCHES

- 7075 AL / Titanium Hardware / Ceramic Finish

- Flip it for a 10mm lower stack height

- 35mm Bars / 42 & 50mm Reach / 139 & 161g

Black w/ silver logos & gold pins – $169.99

Black logos +$12

Choice of hardware color +$20

Custom color w/ silver logos +$40

Custom color & logos +$70

PRE-ORDER ($50 deposit)

Our first production run will be limited. Reserve your’s now.

CUSTOM COLORS: We will email/call you to select custom colors so we can make sure we get you exactly what you want.

Teknika Development

The Teknika products (1) start with a premise and concept; either something patently different or a twist on something that hasn’t been taken as far as it can go. Then (2) we spend a lot of time working this out virtually in Shapr3D which is a fantastic industrial design program that fully integrates with Solidworks and CAD/CAM software. Once we have something we believe is a solid concept, we (3) 3D print it in carbon composite with our Markforged Mark II printer. The print isn’t quite strong enough to ride, but we can mount it to a bike and check fit and function. From there, (4) we go to CNC machined samples to ride test. Changes and iterations are done throughout the process. Once we settle on a finished design, we (5) create final samples that go through a full run of industry standard testing.

Here are some images of the development of the mountain stems.