![]()

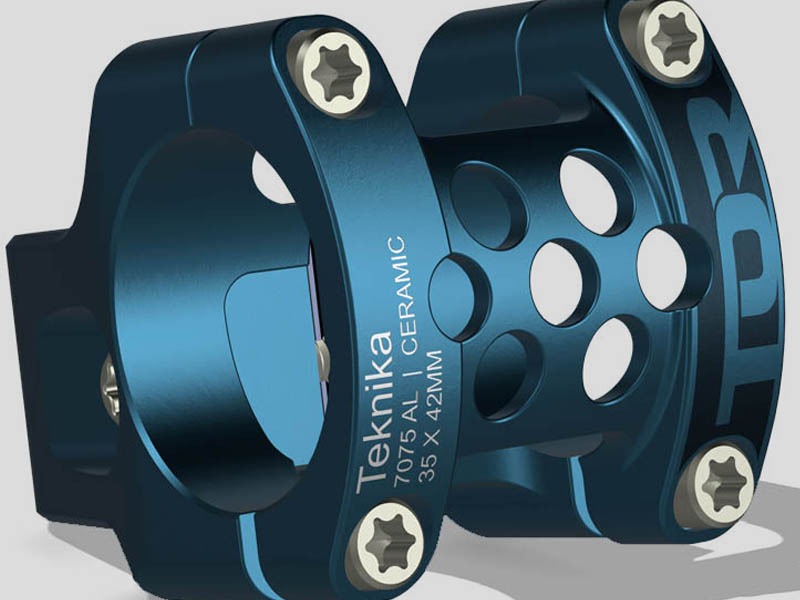

THE CONCEPT | MTN STEMS | DM STEMS | PEDALS | CRANKS

COMING IN LATE SPRING

Teknika Development

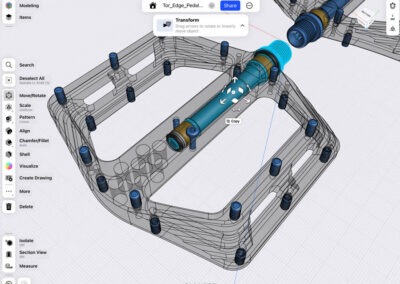

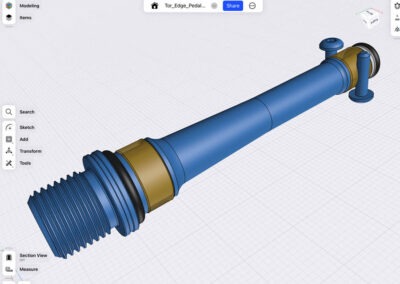

The Teknika products (1) start with a premise and concept; either something patently different or a twist on something that hasn’t been taken as far as it can go. Then (2) we spend a lot of time working this out virtually in Shapr3D which is a fantastic industrial design program that fully integrates with Solidworks and CAD/CAM software. Once we have something we believe is a solid concept, we (3) 3D print it in carbon composite with our Markforged Mark II printer. The print isn’t quite strong enough to ride, but we can mount it to a bike and check fit and function. From there, (4) we go to CNC machined samples to ride test. Changes and iterations are done throughout the process. Once we settle on a finished design, we (5) create final samples that go through a full run of industry standard testing.

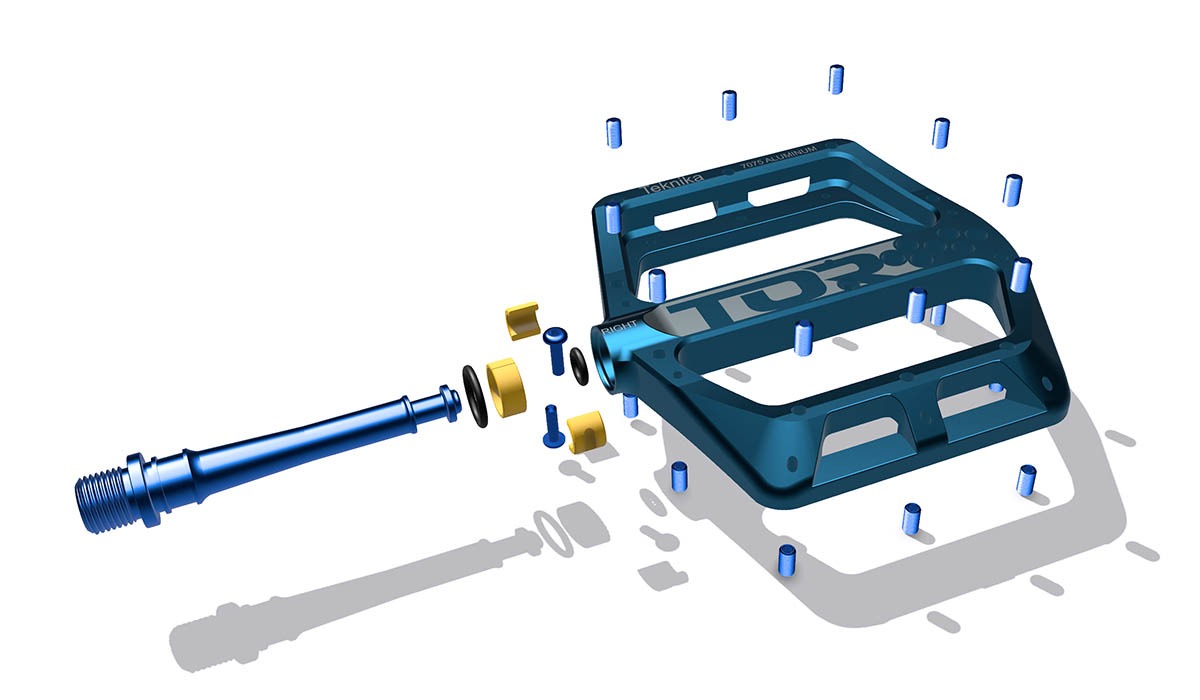

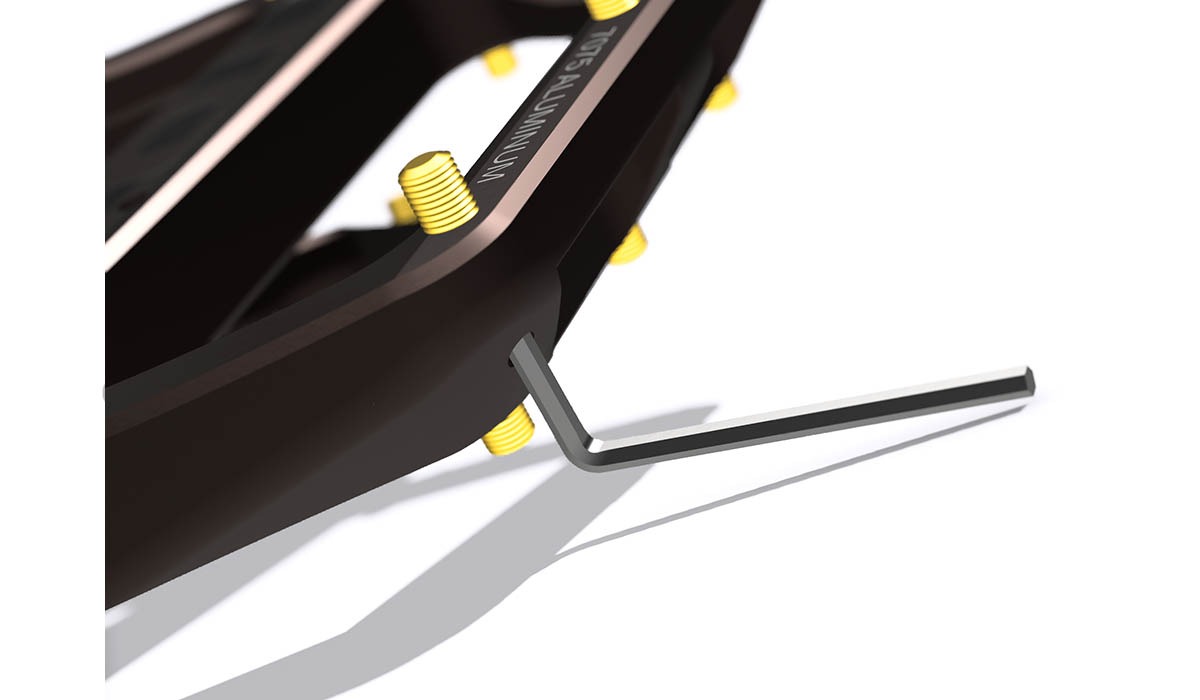

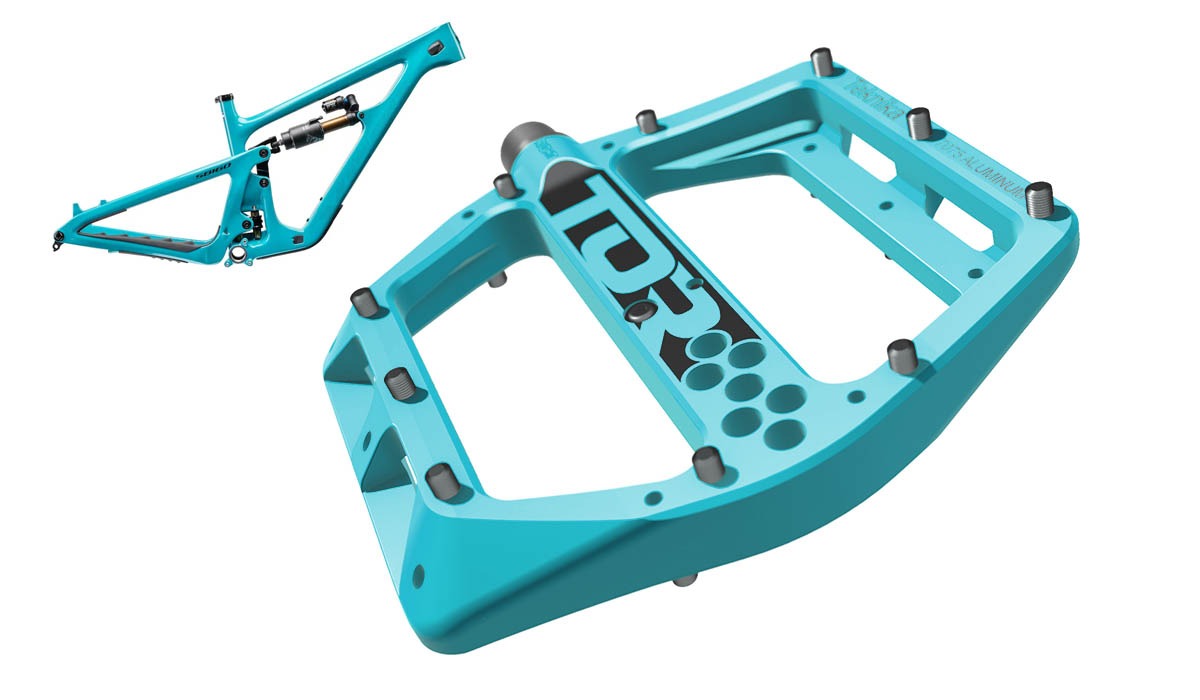

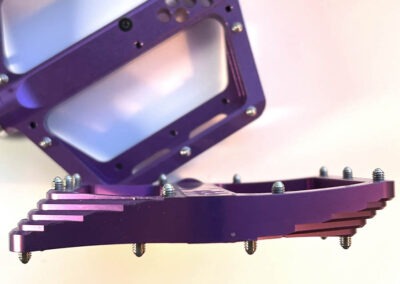

Here are some images of the development of the pedals. Click here to see a video of an early carbon 3D print

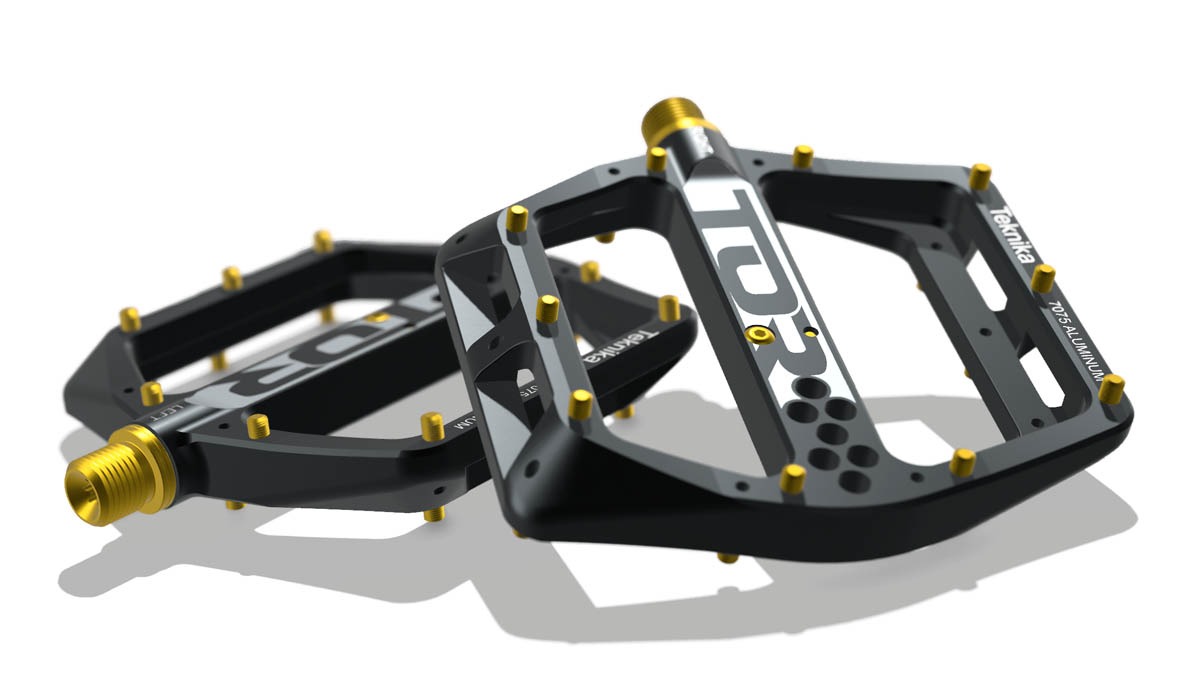

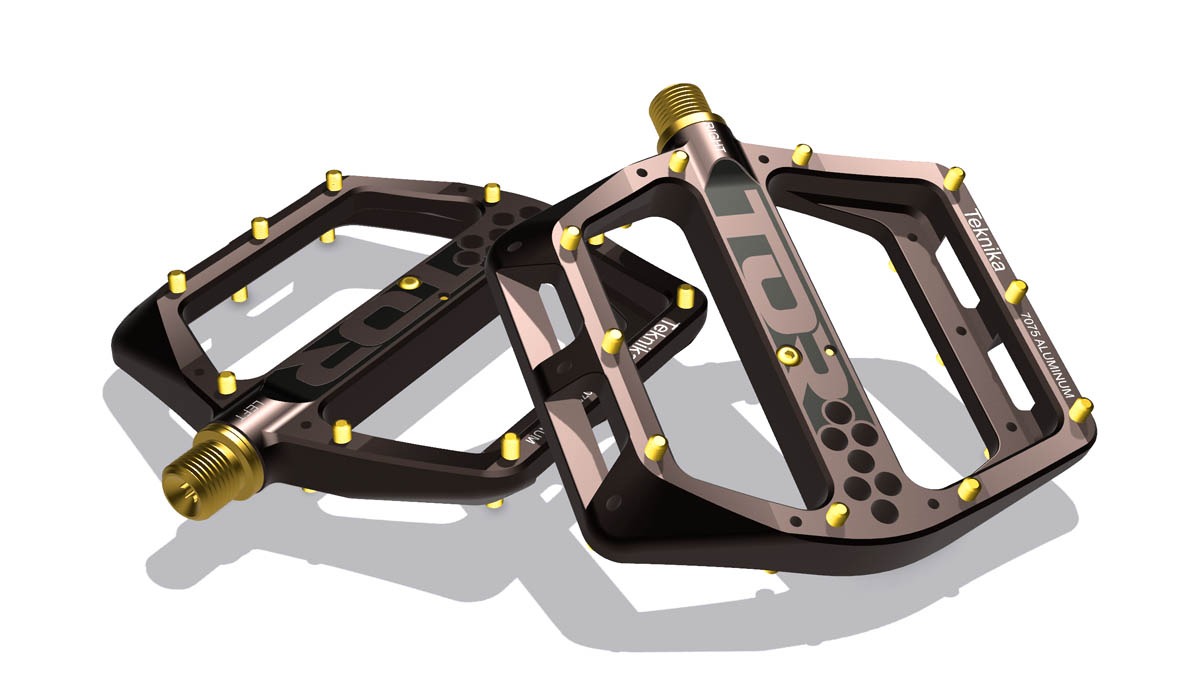

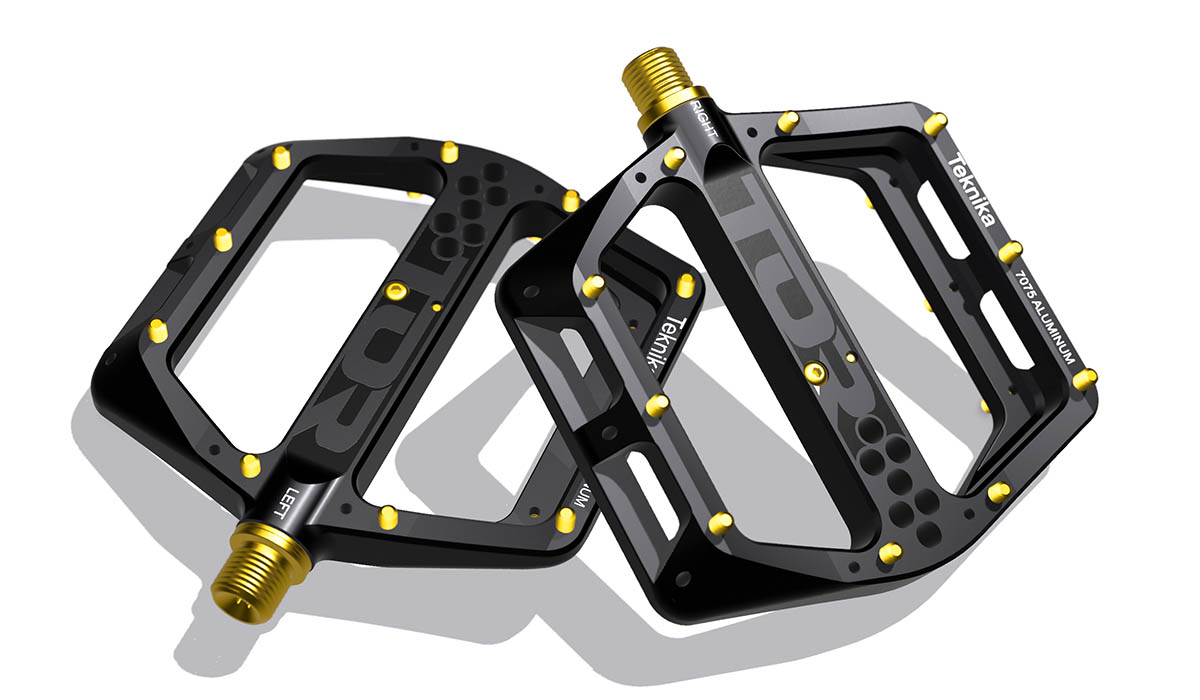

CNC PLATFORM PEDALS

The ultimate platform pedals. Perfect concave, adjustable pins, easy-maintenance self-extracting bushings, and the finest materials. These pedals are CNC machined from 7075 aluminum and come with titanium spindles and traction pins. Available in custom Cerakote colors – SEE CERAKOTE COLOR SWATCHES

- 7075 AL / Titanium Hardware / Ceramic Finish

- 13.5mm thick / 116×108 / Igus Bushings / 370g

Black w/ silver logos & gold pins – $259.99

Black logos +$30

Choice of spindle/pin color +$30

Custom color w/ silver logos +$80

Custom color & logos +$120

PRE-ORDER ($60 deposit)

Our first production run will be limited. Reserve your’s now.

CUSTOM COLORS: We will email/call you to select custom colors so we can make sure we get you exactly what you want.

Teknika Development

The Teknika products (1) start with a premise and concept; either something patently different or a twist on something that hasn’t been taken as far as it can go. Then (2) we spend a lot of time working this out virtually in Shapr3D which is a fantastic industrial design program that fully integrates with Solidworks and CAD/CAM software. Once we have something we believe is a solid concept, we (3) 3D print it in carbon composite with our Markforged Mark II printer. The print isn’t quite strong enough to ride, but we can mount it to a bike and check fit and function. From there, (4) we go to CNC machined samples to ride test. Changes and iterations are done throughout the process. Once we settle on a finished design, we (5) create final samples that go through a full run of industry standard testing.

Here are some images of the development of the pedals. Click here to see a video of an early carbon 3D print